That's nice. I've always wanted a

dividing head; one that could accommodate rigid fixturing, be infinitely adjustable in terms of it's potential divisions; and, lastly, it's cost must not be so dear as to be found unequal to penniless-tinker society. So, where my machinists at?

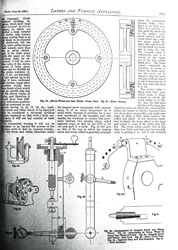

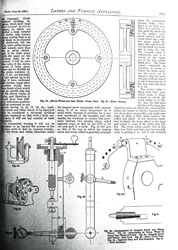

This week, "Lathes and Turning Appliances" features a lathe mod for ornamental turners. It's called The Worm Wheel and Tangent Screw.

ARTICLES FOUND IN THIS ISSUE:

MY DOUBLE MUSIC STAND: HOW I MADE IT

•

"LINING UP"

•

THE TENANT'S GREENHOUSE

•

LATHES AND TURNING APPLIANCES

•

JAPANESE MOTIVES FOR FRET CUTTING, ETC.

•

"TIPS" FOR TYROS

•

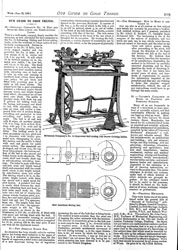

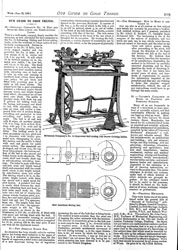

OUR GUIDE TO GOOD THINGS

•

SHOP: A CORNER FOR THOSE WHO WANT TO TALK IT

<But you can't fool me. This is a

dividing head; or at least it's a kind of proto-dividing head. As you can tell from the drawing, the parts described bolt onto the lathe's headstock. It doesn't quite make it a stand alone device, unless, of course, you're comfortable removing the headstock of your lathe. (I don't know anybody who is comfortable with this.)

What good is this? Well, if you've got an ornamental turning lathe and you want to cut flutes, or helices, or any feature that requires regular and precise spacing around the radius of a workpiece, this is a pretty helpful piece of kit.

Unattached to a lathe, a proper dividing head can be used in conjunction with a milling machine for short-run

gear shaping as well as fabricating a host of other fun mechanical components.

Trouble is, a good, old, indexing head like the one I want is an expensive purchase for a personal shop. It's right up there next to

rotary table on the list of shop toys I wish I had but have managed to do without for years.

For some time now, I've suspected that, given time and careful planning, I might be able to make one for myself. The worm wheel & tangent screw design presented this week, gives my as-yet unmanifest machinations a helpful kick in the pants. The complex castings that comprise housings for "modern" dividing heads always stymied my motivation. Now I realize I can just skip them altogether and plan something not unlike a detached lathe headstock.

I realize that my personal breakthrough doesn't represent such a staggering conceptual leap, but plenty of folks will admit that, in the realm of elective projects, a good image of what your project will look like at the end has a lot of influence over whether or not you even start.

–TIM

Click to Download Vol.1 - No. 14 •

Disclaimer: Articles in Work: The Illustrated Weekly Journal for Mechanics describe materials and methods that would not be considered safe or advisable today. We are not responsible for the content of these magazines, and cannot take any responsibility for anyone attempting projects or procedures described therein.

The first issue of Work was published on March 23rd, 1889. The goal of this project is to release digital copies of the individual issues starting on the same date in 2012, effectively republishing the materials 123 years to the day from their original release.

The original printing was on thin, inexpensive paper. There are many cases of uneven inking and bleed-through from the page behind. Our copies of Work come from bound library volumes of these issues and are subject to unfavorable trimming, missing covers, etc. To minimize harm to these fragile volumes, we've undertaken the task of scanning the books ourselves. We do considerable post processing of the scans to make them clear but please bear with us if a margin is clipped too close, or a few words are unreadable. We would like to thank James Vasile and Karl Fogel for their help in supplying us with a book scanner and generally enabling this project to get off the ground.

You are welcome to download, print, and pretty much do what you want with the scan for your own personal purposes. Feel free to post a link or a copy on your blog or website. All we ask is a link back to the original project and this blog. We are not answering requests for commercial downloads or reprinting at this time.

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine